The Autocar, 1898:

“It is some nine months since I wrote an article in The Autocar, giving an idea of the progress made by his automobile firm, and those of your readers who recollect the details will be astonished at the rapidity with which Messrs. De Dion and Bouton almost completely transformed their business, models, machinery, and works into a gigantic concern. This speaks volumes for the energy displayed by the genial Count Albert de Dion, whom I rightly mentioned in my last article as being the ” life and soul of the automobile industry and sport”. He is always in evidence, either “at the helm” in his works, or taking part in motor races, discussions relating to the industry, practically or technically; in fact, he is bound up heart and soul in the motor industry, and is constantly on the alert for suggestions of improvement.

The Count is ably seconded at the works, in the practical part of the business, by Monsieur Bouton, and in the shops, technically, by Monsieur Gasselin, whilst, commercially, Monsieur Locoeur and his able son are indefatigable.

Great changes have taken place during the past few months, changes so important that I feel impelled, in order to complete this subject, to go over again some of the ground already traversed. This course will go a long way to confirm what I have already said as to the progress made, more so than anything else I can conceive. I am, thanks to the courtesy of the firm, able to illustrate these articles with photographs which I have specially taken for The Autocar.

It is all the more necessary to treat this subject comprehensively, as I am pleased to state, for the future interest of the English motor movement, that Messrs. De Dion and Bouton have secured a British license from the British Motor Co., Ltd. -the syndicate which has purchased over thirty of the De Dion English patents to supply the De Dion celebrated motor tricycles, safeties, quadricycles, light carriages, and steam omnibuses of the De Dion manufacture, bearing the De Dion trade transfers, direct from their works to Great Britain and her colonies. Negotiations are being entered into whereby agents will be appointed to represent the De Dion firm in England and Colonies, and shortly correspondence will be conducted in English, whilst an illustrated English catalogue is in preparation.

Therefore, in 1899, the motor industry should rapidly progress in England as in France, seeing that it is undoubtedly the ” De Dion tricycle that has been the means in Paris and provinces of making the motor industry so popular. Hundreds of these tricycles are to be seen at every turn “puffing”, some gently, some swiftly, on the Boulevards, over the smooth roads in the charming Bois de Boulogne or Vincennes, intermingled with motor cars, until the Parisian has learned to regard them only as an ordinary fin de siècle mode of locomotion. Visitors from abroad are at first somewhat astonished at the number of persons motoring, especially when a fair Parisienne rapidly flits past on a ” De Dion ” tricycle. Such an apparition is quite sufficient to make the stranger say, ” Well, if ladies take to riding motor tricycles, and drive motor cars, like the Duchess d’Uzes, they are bound to be successful in England.

English tourists returning from Paris must be forced to the conclusion that England is not at all up to date in modern mechanical road locomotive improvements. One English lady exclaimed to me, “We are proud of our men-of-war that “rule the waves”, but the French masters of the highways with motor cars”. That the autocar industry in France is most flourishing, commercially and financially, will be evident from what follows, and I will give a few authentic figures which will convince the most skeptical persons. Messrs. De Dion and Bouton have not only been building motors, motor tricycles, and steam omnibuses, but the rapid growth of their business has necessitated a continual increase in their workshops over enormous new tracts of ground recently purchased for the purpose, until their premises now cover an area of about 30,000 square meters.

To agents and cycle makers who literally besiege the De Dion works, praying to get early supplies of motors or tricycles, the only reply that can be given is to show them round the new factories, in order to prove to them that every effort is being made to cope with the demands.

Visitors are politely informed that they are certain to get satisfaction later on. As a sign of the times, Messrs. De Dion and Bouton have just opened a large depôt with repairing shops in the Avenue de la Grande Armée, but the shutters are closed down, and a large board is fixed over them bearing the following announcement in large letters : “Les commandes surpassant en ce moment la production l’exposition des véhicles au!omobiles de la Maison De Dion et Bouton ne sera ouverte qu’ultérieurement.”

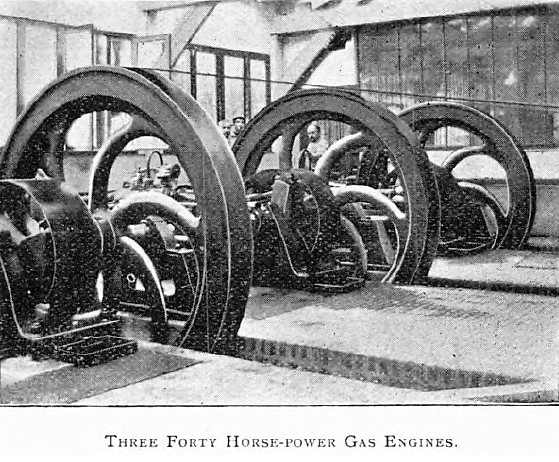

This is unique almost in any industry I know of, but that the firm is-doing all that is possible to meet the demands of the situation is proved by the activity that reigns supreme throughout the works, and also upon the adjoining land, where building operations are proceeding apace. A tunnel has been made under the Rue Ernest to connect the old works with the new premises across the road. After getting through this subterranean passage, the visitor sees three large gas engines, made by Crossley Bros. , driving the dynamos, which in their turn supply motive power to the shafting throughout the new workshops.

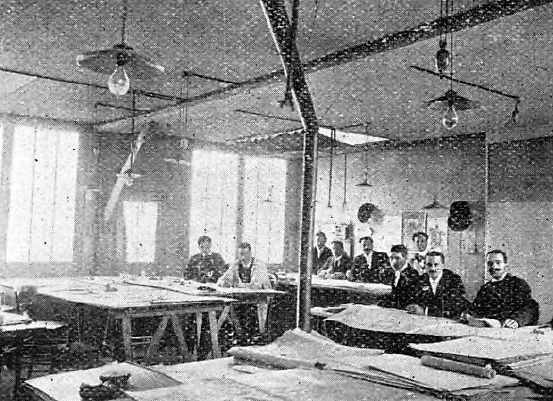

There is a space reserved alongside these gas engines, that seven more similar engines may be put in as required. With a view to economy, workmen are busy fitting up the necessary apparatus for making gas on the premises. In December last there were only 250 workmen employed in the manufacture of motors and vehicles, but to-day there are close upon б00, including the administrative staff. The drawing office is kept constantly busy preparing designs for new models or improvements which are almost daily introduced in one or another of the many vehicles which are in course of construction, or which have not yet left the designer’s hands.

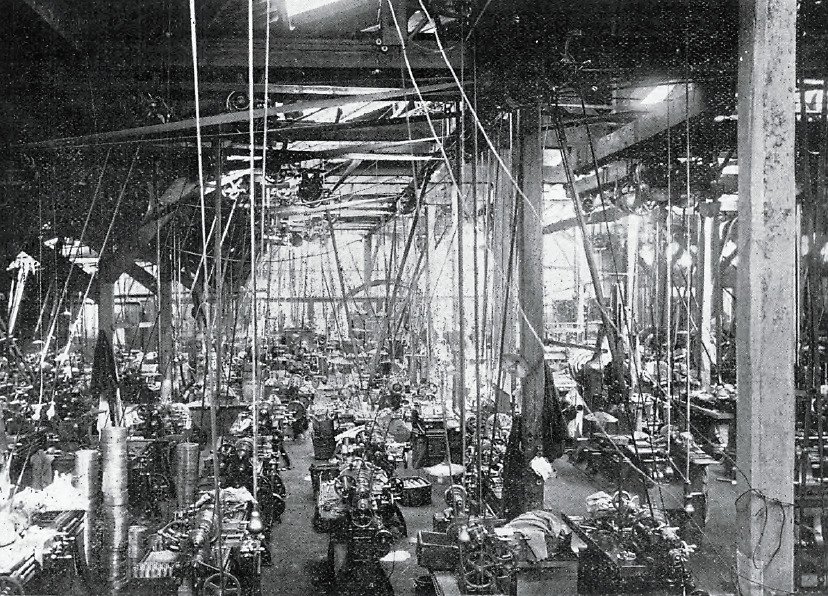

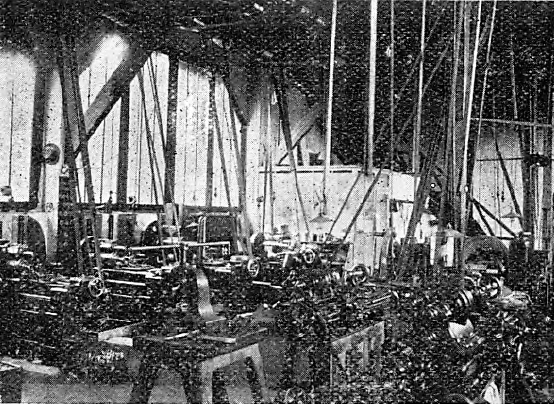

Loads of new machinery of French, English, German, Belgian, or American origin, are daily being brought into the works. The large proportion of the machines, however, are from America, these possessing the advantage of being constructed on automatic labor-saving principles.

The number of modern machine tools at work in the factory is surprising, and the factory itself is magnificently fitted up absolutely regardless of expense.

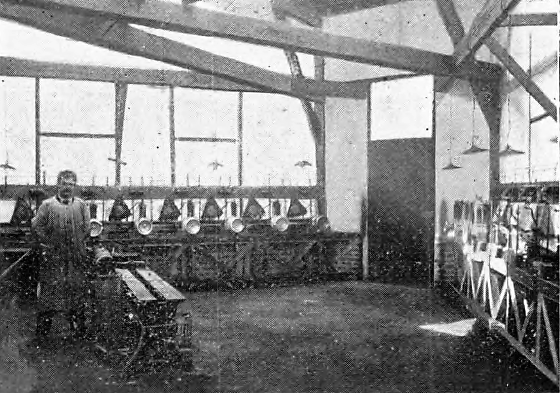

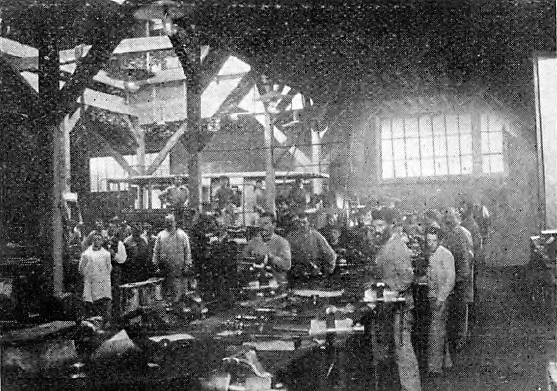

An enormous fly-wheel will be noticed in the photograph at the head of this article; this belongs to the one hundred horse-power steam engine which is running the shafting in the old part of the works. The next turning shop is a new wing across the road, where the latest American machinery is being used. A smaller shop is fitted up with some Yankee tools and others from Coventry which finish several motor parts right up from the solid bar, and, of course, necessitate the workmen taking the jobs on piecework.

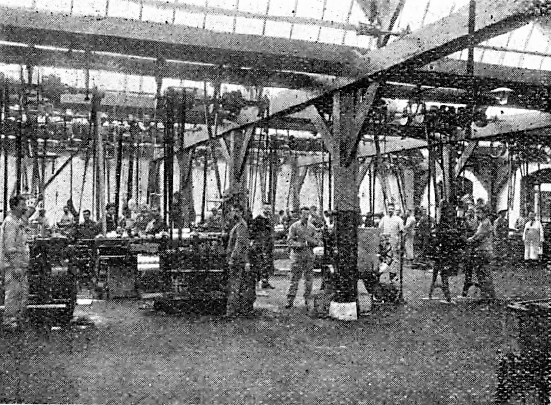

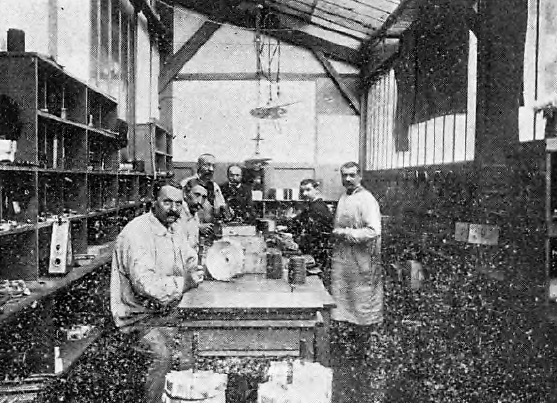

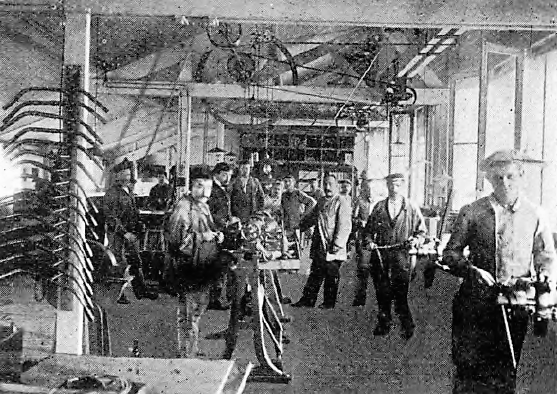

In the motor industry it is exceedingly important that every part of the motor, especially the cylinder, piston, and valves, should be finished exactly to gauge and made to fit and run together perfectly. The De Dion Works, therefore, being furnished with proper machinery and tools, can turn out the various parts in such a manner that they possess the desirable “sine qua non” of being absolutely interchangeable. This will account for the fact that all stages of the work are carried out by old experienced hands, as shown in the photograph.

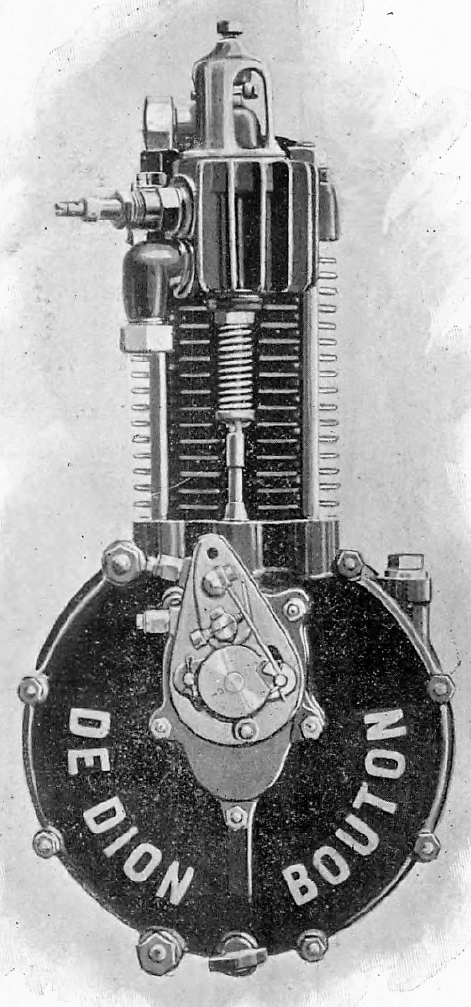

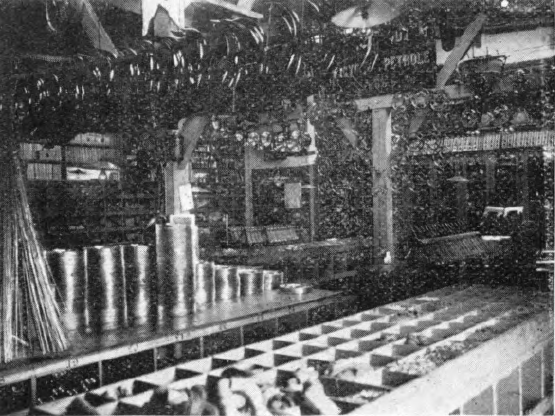

The one and a quarter horse-power motor has been entirely abandoned as unsatisfactory; it did not give sufficient driving power for uphill work. Messrs. De Dion and Bouton have succeeded in turning out, regularly, five hundred one and three quarter horse-power motors per month, and the picture on the preceding page will show one side of a square shop where they are fitted together.

A short description of the new 1898-99 pattern one and three quarter horse-power motor, which has superseded the old one and three quarter made at the commencement of this season, will be interesting. The bore of the cylinder is sixty-six millimeters, and the principal modifications are in the inlet and exhaust valves. The former is now fitted with a detachable bell-top with open sides to occasion a current of air, which assists in cooling the top of cylinder. It is now easy to take out the valve for cleaning or other purposes, whilst the sparking plug is placed in a more convenient position, One of the main features in the construction of a De Dion motor, and which has greatly promoted its wonderful success, is that each motor is submitted to a most severe and careful test before being passed. They are kept running at 1,800 to 2,000 revolutions per minute for twenty-four hours, a week, or more, until it gives the one and three-quarter horse-power, and is marked “efficient.

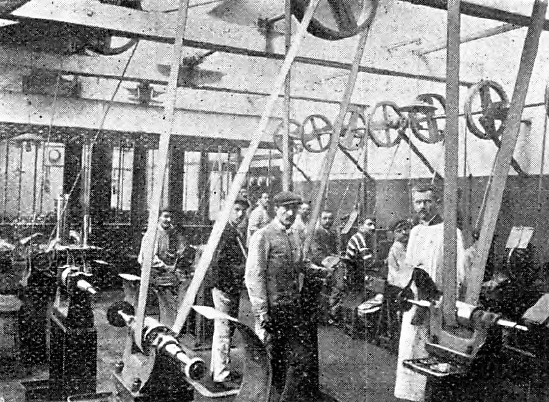

As will be seen by the above picture, the testing shop is fitted up in a most practical manner. Thirty motors can be tested at one time, each being fitted with its own petroleum tank and electric coil, so as to be run separately and adjusted into proper working order previous to being placed upon the tricycle.

The electric department of the works has attained an important position, the electric sparking, as now fitted to the motor, being undoubtedly “half the tricycle”, as a well-known motoring man designated the electric ignition, especially now that accumulators have been abandoned, and the dry battery has come to the rescue. The new dry battery will supply sparking to the motor for about 500 working hours, but when it has run out, it is useless, and is thrown upon the scrapheap. New batteries, however, can be bought . thirty shillings, which means, in plain English, that the tricycle can be ridden, before the first 500 hours are exhausted, a distance of about seven or eight thousand miles for thirty shillings, without any recharging an operation which formerly proved such a nuisance.

The new dry battery has been reduced to child’s play. Care must, however, be taken to pull out tie connecting plug, which is placed in a convenient position along the top tube, beneath the dry battery, and place it in the pocket, so as to make it impossible for the battery to run out. Street urchins may then, if it is left unattended, turn the connecting handle to their heart’s content without any effect.

I may mention in passing that I have prepared a separate article for a later issue of The Autocar, dealing with the various technical and practical advantages of electric ignition for motor cycles from the ordinary rider’s point of view.

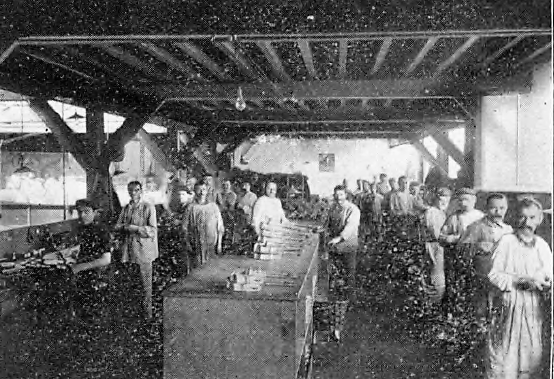

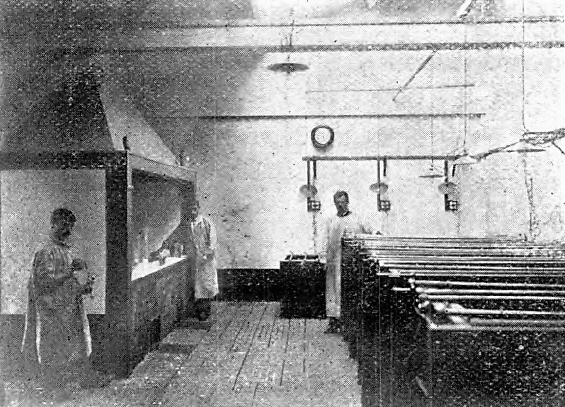

The workshop represented below is where the connecting handle or switch is fitted in the handle-bars of the tricycle, and other electric work carried out.

In the new wing, across the road, adjacent to the gas engines, are the polishing shops which need no description ; suffice to say, they form one of the necessary departments of the new buildings.

Next to the polishing shops, of course, comes the nickel-plating, and, whilst at this stage of the building, it may be interesting to mention that the factory is entirely illuminated by electricity, and that the same current is used for the nickel baths.

It is with a feeling that the firm means business that one passes the rooms, for they are literally packed with goods, representing thousands of pounds, which are in course of making their passage through the works, and which give place daily to others of equal value.

Having completed the visit to the works, and witnessed the various processes of manufacture turning, fitting, and what not I was pleased to see the finished goods which had resulted from such a complication of machinery and operations. Specimens of the products of this line of industry confronted me when I reached the fitting-up and finishing shop, in the form of a series of twenty-four tricycles in a double row, just receiving the last finishing touch, as portrayed in the illustration at the head of this article. It was evident from all that I had seen that the motor industry is no mere French “passing fallacious fancy”, but a genuine, sound, solid, business, destined to become yet more important in the future. It is not surprising either that this new form of locomotion is making itself felt upon the cycle industry as a competitor that has come to stay.

The business of the steam omnibus department is gradually growing till it has become too large for the accommodation allotted to it. All concerned will, therefore, be pleased to get more elbow room across the road. It is difficult to cope with the demand for omnibuses, as their success is decidedly genuine, their services be, ng requisitioned particularly in the provinces and colonies, where the railway or diligence service is incomplete. The next photograph will show several buses in course of construction.

It will be interesting to quote a few official figures to me by Monsieur Lecoeur respecting the firm’s present turnover. Their monthly cash returns for wholesale and retail business average 20,000, including motors, complete tricycles. Steam omnibuses, etc. The firm is turning out, regularly, 200 complete tricycles, and supplying other manufacturers with 300 separate motors, which make a total of 500 motors per month, including the above 200 tricycles.

Messrs. De Dion and Bouton have actually on their books orders for delivery next year of machines valued at over 3,000,000 francs (120,000 pounds), and further orders are coming in daily.

They have orders for motors and tricycles from Germany alone to the value of 25,000 pounds. With these figures in my mind, I naturally asked, ” Well, how will you supply English orders, now that you have the right to supply machines to that country direct ?? The reply was not made in words, but it was to be inferred from what I was shown of the drawings of the new 1899 buildings, which will be ready in January next, and which will cover an area of about 10,000 square meters. The reply was also emphasized by a visit to the ground which was being prepared to receive the new buildings.

I said, “But you will never have the new buildings up by January next.”

“Oh, yes we shall. We have purchased the iron girder frames of the buildings that were used during the 1889 Paris Universal Exhibition, which are very well adapted to our requirements. “

This put a different complexion on the matter at once, and I was further informed that part of the machinery with which to equip the new factory was already en route from America and elsewhere.

The second photograph will show that portion of land which is being prepared to receive the exhibition buildings just referred to, the dimensions of which are 100 meters wide by about 150 meters in length. These will represent one span of shops.

To sum up the situation, it has been decided to employ, if necessary, 2,000 workmen, capable of turning out 60,000 pounds worth of motors, complete tricycles, quadricycles, light carriages, and steam omnibuses, per month, and, judging from the progress made during the past nine months, I shall not be surprised, in the least, if this time next year Messrs. De Dion and Bouton have surpassed their own expectations.”